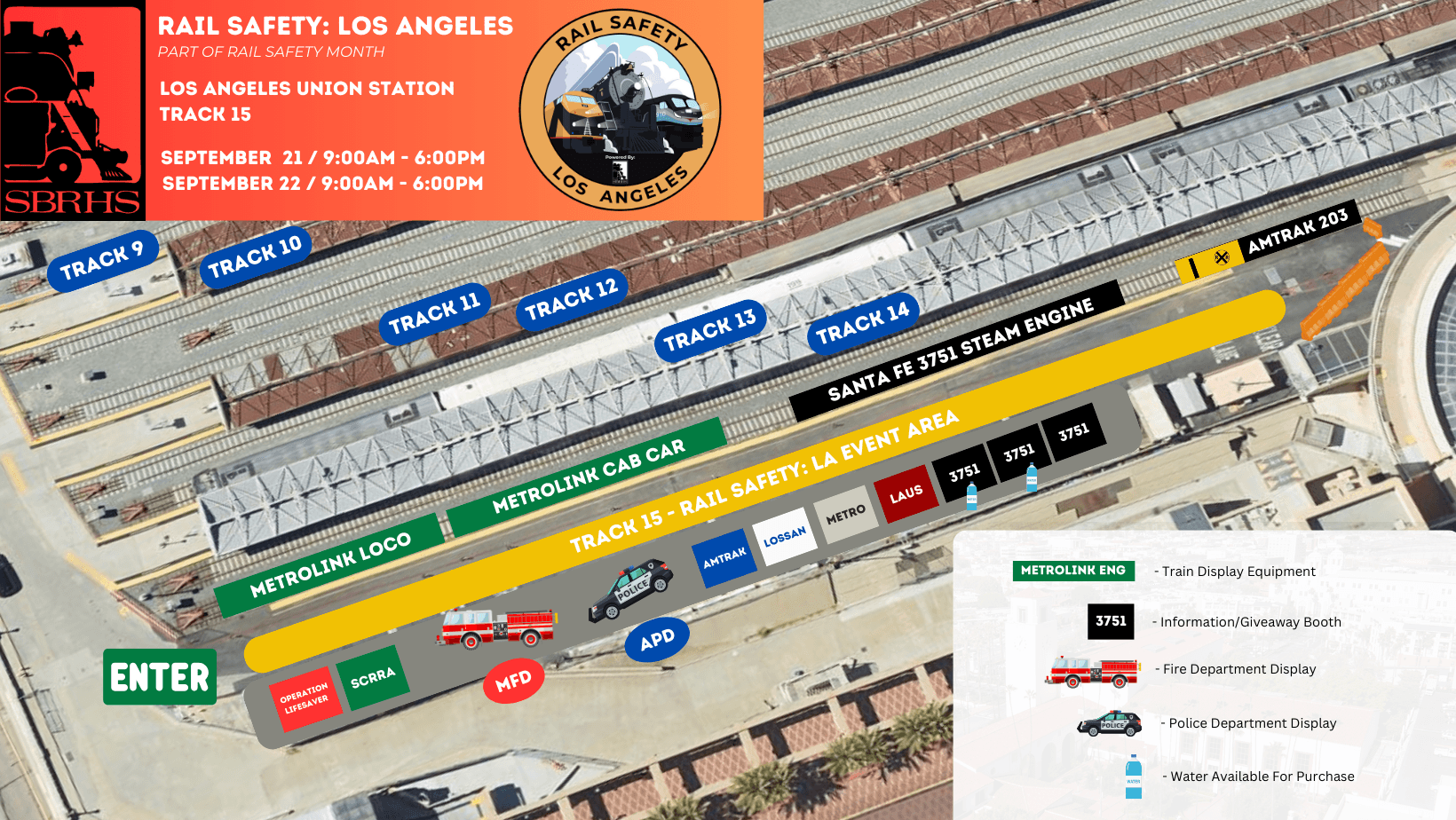

Join us September 21 - 22 at Los Angeles Union Station 9:00 a.m. - 6:00 p.m. Daily For This FREE Event

The San Bernardino Railroad Historical Society (SBRHS), with presenting partners Los Angeles Union Station, Metro, Metrolink, and Amtrak, will welcome the public to Rail Safety: Los Angeles this September - the largest railroad safety event in downtown Los Angeles in more than a decade, as part of Rail Safety Month.

The SBRHS’ historic, 1927-built steam locomotive, Santa Fe 3751, will headline the free, two-day event on Track 15 of Los Angeles Union Station on Saturday, September 21, and Sunday, September 22, from 9 a.m. to 6 p.m. daily. The 3751 will be joined by some of today’s most modern Metrolink and Amtrak passenger train equipment and information booths, providing a unique educational opportunity for attendees to learn about the size, scale, and speed of trains and learn new ways to be safe around railroad tracks.

TRAIN DISPLAY EQUIPMENT

Santa Fe 3751 Steam Locomotive

Since its incorporation in 1981, the San Bernardino Railroad Historical Society (SBRHS) has engaged in the acquisition, preservation, restoration, and public exhibition of Santa Fe Railroad history, artifacts, and equipment. Between 1986 and 1991, the SBRHS restored the Santa Fe 3751 steam locomotive, built in 1927, back to operating condition. The locomotive has been a real-life educational tool for over 30 years. The SBRHS has successfully run Santa Fe 3751 as far east as Chicago, IL, as far north as Sacramento, CA, and as far south as San Diego, CA. The engine has also visited the Grand Canyon twice. Santa Fe 3751 holds the title of pulling the first passenger train into Los Angeles Union Station on May 3, 1939, has starred in several movies, and was placed on the National Register of Historic Places in October 2002. Be sure to follow @santafe3751 on social media.

Amtrak 203 - Operation Lifesaver Unit

Amtrak’s one-of-a-kind Operation Lifesaver painted locomotive, Amtrak 203, will also be on display at Rail Safety: Los Angeles. This diesel-electric P42-DC locomotive is the only unit in Amtrak’s locomotive fleet that features a special yellow and black paint scheme, symbolic of railroad crossing signs, which it received in 2022 as part of Operation Lifesavers' 50th Anniversary.

Metrolink F125 Unit

The F125 "Spirit" is a four-axle passenger diesel locomotive manufactured by Electro-Motive Diesel (EMD) since 2015. The locomotive is powered by a Caterpillar C175-20 V20 diesel engine rated at 4,700 hp (3,500 kW). A single F125 is capable of traveling at a maximum in-service speed of 125 mph (201 km/h) pulling consists of up to 10 cars.

Metrolink Cab Car

Metrolink proudly introduced the next generation of cab and passenger rail cars to the agency's fleet in 2010. As part of an order of more than 115 railcars, the new equipment incorporates the latest in Crash Energy Management (CEM) technology, including redesigned seats and work tables and advanced energy-absorbing zones at each end of the cars. Metrolink is the first passenger train service in the nation to include CEM in its passenger cars as part of its commitment to bring 21st Century safety technologies to Metrolink’s rail system.

VEHICLE DISPLAY EQUIPMENT

Amtrak Police Department Patrol Vehicle

Montebello Fire Department Apparatus

Los Angeles City Fire Department Apparatus

OTHER PRESENTING PARTNERS

Los Angeles Union Station

Since its opening in 1939, Los Angeles Union Station has long been considered one of LA's architectural gems and a vital portal to the promise of the California Dream. The Station was designed with an innovative blend of Spanish Colonial, Mission Revival and Art Deco architecture now commonly referred to as Mission Moderne. The bustling 52-acre transportation hub sits in the heart of Downtown Los Angeles offering essential connections to destinations throughout Southern California. An iconic landmark, the Station serves as a vibrant symbol of Downtown connecting the historic fabric of the past to the present through arts, culture, transit and community. Conceived on a grand scale, Los Angeles Union Station is the largest railroad passenger terminal in the Western United States and is often regarded as "the last of the great train stations." For more information, visit unionstationla.com or follow @unionstationla on social media.

Metro

The Los Angeles County Metropolitan Transportation Authority (Metro) is building the most ambitious transportation infrastructure program in the United States and is working to greatly improve mobility through its Vision 2028 Plan. Metro is the lead transportation planning and funding agency for L.A. County and carries nearly a million boardings daily on four light rail and two subway lines and 119 bus lines utilizing more than 2,000 low-emission buses.

Stay informed by following Metro on The Source and El Pasajero at metro.net, facebook.com/losangelesmetro, twitter.com/metrolosangeles and twitter.com/metroLAalerts and instagram.com/metrolosangeles.

Operation Lifesaver - California

As an independent non-profit organization, California Operation Lifesaver relies on the support of private citizens and corporations, state and local transit organizations, as well as our devoted and energetic team of Authorized Presenter Volunteers. All of our supporters have the CAOL Mission at the heart of their dedicated participation. We join together with a mutual goal to raise awareness to eliminate track tragedies at highway-rail grade crossings and along railroad rights-of-way in California. CAOL works all year long to change dangerous behaviors that cause preventable injuries and loss of life.

LOSSAN

The LOSSAN Rail Corridor Agency (Agency) is a joint powers authority originally formed in 1989 that works to increase ridership, revenue, capacity, reliability, coordination and safety on the coastal rail line between San Diego, Los Angeles and San Luis Obispo. It is governed by a 11-member Board of Directors composed of elected officials representing rail owners, operators, and planning agencies along the rail corridor. The LOSSAN Agency is staffed by the Orange County Transportation Authority.

The 351-mile Los Angeles – San Diego – San Luis Obispo Rail Corridor (LOSSAN Corridor) travels through a six-county coastal region in Southern California and is the second busiest intercity passenger rail corridor in the United States and the busiest state-supported Amtrak route. The LOSSAN Corridor service includes 41 stations and more than 150 daily passenger trains, with an annual ridership of nearly 3 million on Amtrak Pacific Surfliner intercity trains and 5 million on Metrolink and COASTER commuter trains.

THANK YOU

The SBRHS would like to thank the following agencies for their support of Rail Safety: Los Angeles